April 17, 2024

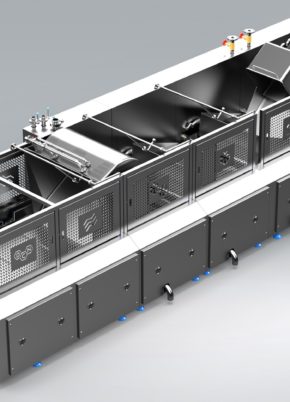

A COMPREHENSIVE WHITE PAPER: COOK QUENCH CHILL ‘ADAPT’

Learn more

April 17, 2024

Learn more

March 12, 2024

In the world of food manufacturing, efficiency is paramount. Whether you’re a small-scale producer or a larger operation,…

Learn more

February 27, 2024

Learn more

February 16, 2024

Learn more

February 13, 2024

Beerenberg, a family-owned business rooted in South Australia since 1839, has evolved from a humble strawberry farm to…

Learn more

January 29, 2024

To celebrate the Scottish tradition of Burns night we wanted to share our recent Haggis process training trial…

Learn more

November 29, 2023

In a significant milestone for DC Norris’ new Cook Quench Chill ‘Adapt’ system, we have now received orders for seven machines during a twelve-month period. The latest order is set to enhance the operations of a renowned Ready Meals manufacturer located overseas, underlining the system’s growing popularity and global demand.…

Continue reading

November 23, 2023