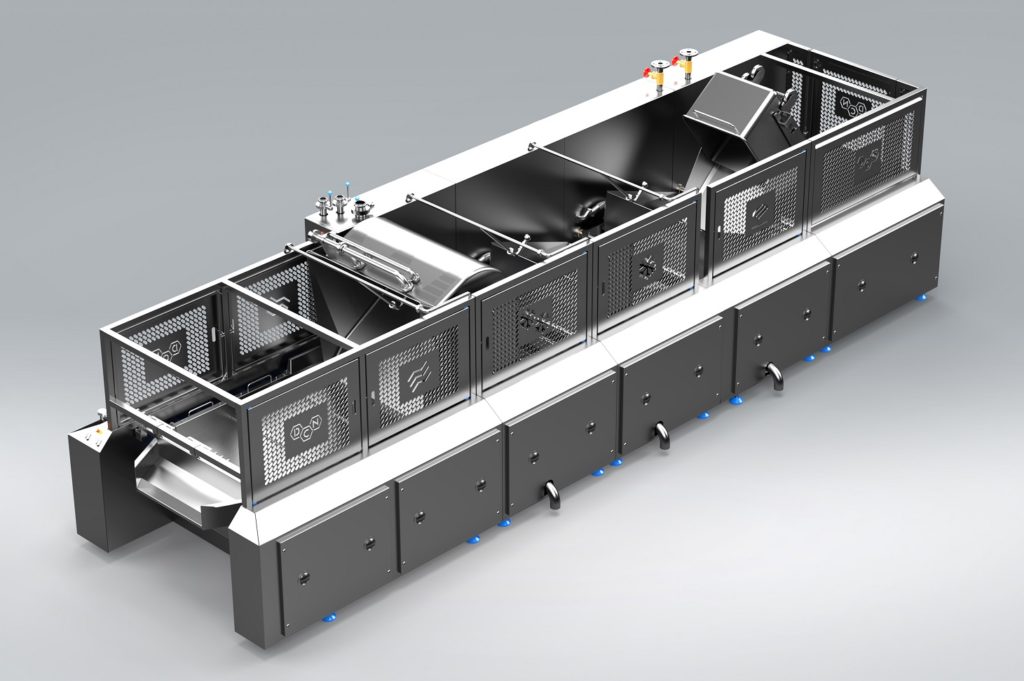

At DCN, we bring together the best of traditional cooking methods and cutting-edge technology with a unique combination of the DCN Jet Cook, Braising Bar, Steam Jacket, and Recipe Management System.

This innovative setup allows us to create a wide array of soups and sauces, whether they have a thin viscosity like tomato soup or contain large particulates such as grains, meat, and vegetables. Thanks to the versatility of the Jet Cook, our system can effortlessly produce diverse products like minestrone, béchamel sauce, curries, and barbecue sauce all on the same platform.

The design of our unit, featuring a 50mm diameter orifice and no moving parts, enables large pieces of meat and vegetables to pass through freely while undergoing rapid heating. This not only reduces excessive cooking time but also minimises the thermal impact on vegetables and fruits. As a result, the loss or dilution of essential vitamins, minerals, and fibres during traditional cooking is significantly reduced.

Our Jet Cook system, along with its conditioning chambers, serves as the heart of this set-up. We’ve remodelled these components to accelerate the movement of liquids even faster, providing greater flexibility when creating emulsions.

The Braising Bar and Steam Jacket play a crucial role at the start of the cooking process, allowing us to create a roux or sear meat and vegetables. This method adds colour and flavour to the dishes and is particularly effective for caramelising onions, enhancing the overall taste profile.

Subsequently, the Jet Cook™ takes over, rapidly and evenly heating the soup to the desired temperature. If needed, the product can be homogenised to create a smooth base for the soup.

Furthermore, our equipment has been thoughtfully designed to reduce the carbon footprint, delivering energy savings of up to 50% when compared to conventional cooking systems. At DCN, we are committed to culinary innovation, sustainability, and ensuring the highest quality in every product we create.

Soups & Sauces Gallery

GET IN TOUCH

Speak to our expert