Jet Cook™

Advanced Cooking Technology for Sustainable Food Production

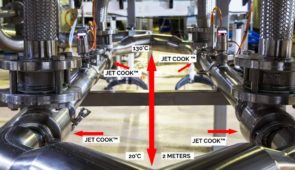

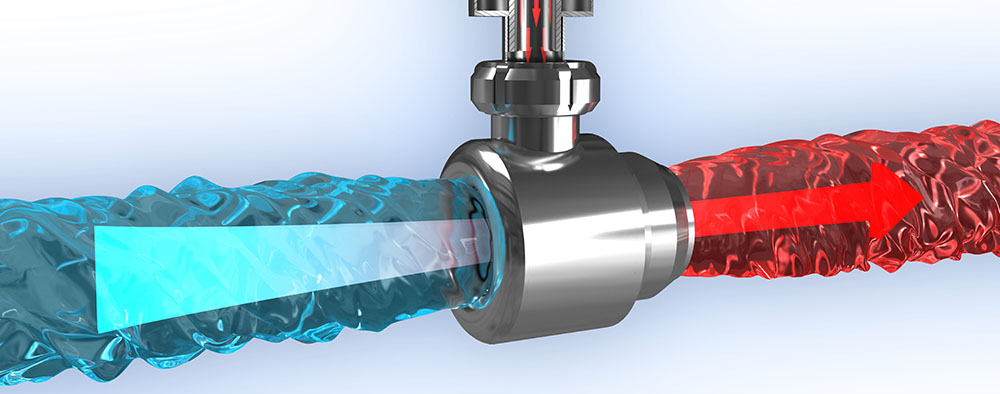

The patented DCN Jet Cook employs high-performance steam technology to provide rapid, versatile, and efficient solutions for processing liquid food, beverages, and wet pet food, enhancing your manufacturing operations.

The system delivers remarkable reductions in processing times and substantially reduces clean-in-place demands, all while maintaining uncompromised quality and flavour. Jet Cook represents a groundbreaking fluid processing solution capable of homogenising, emulsifying, entraining, pumping, and heating with exceptional performance.

DCN Jet Cook can be utilised either In-Tank as part of a DCN Kettle System or In-Line for continuous single pass or re-circulation heating. There are a wide range of options available to enhance your food manufacturing, including Powder Entrainment, Braising Bar and Emulsifiers.

BENEFITS

- Fast Cooking Times – Production times of sauces, dairy products, soups and ready meals greatly reduced.

- Energy Reduction – Approximately 52% when compared with traditional methods.

- Improved Product Quality & Particulate Integrity

- Reduced Processing Stages

- Reduction in Ingredient Quantities

- Small Footprint

- Reduced Cleaning

‘We purchased our first Jet Cook System for the production of meat and particulate sauces for Ready Meals. We then ordered another two systems within six months.’

Robert Graham – General Factory Manager – Greencore, UK

Jet Cook™

Gulfood Manufacturing - Future In Focus

For more Jet Cook™ videos then visit our media page

Downloads