April 23, 2024

Uncover Advanced Food Processing Solutions at Saudifood Manufacturing

Learn more

April 23, 2024

Learn more

April 17, 2024

Learn more

March 12, 2024

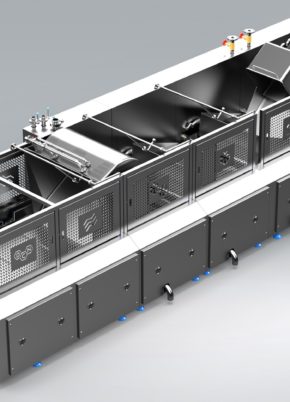

In the world of food manufacturing, efficiency is paramount. Whether you’re a small-scale producer or a larger operation,…

Learn more

February 27, 2024

Learn more

February 16, 2024

Learn more

February 13, 2024

Beerenberg, a family-owned business rooted in South Australia since 1839, has evolved from a humble strawberry farm to…

Learn more

January 29, 2024

To celebrate the Scottish tradition of Burns night we wanted to share our recent Haggis process training trial with one of our customers in Scotland last week. The cherished Scottish dish is a savoury pudding containing sheep’s pluck (heart, liver, and lungs), minced with onion, oatmeal, suet and spices and…

Continue reading

November 23, 2023